Home

Production Standards

Capitalise on low hanging fruit to identify a ballpark value added activity to beta test.

Override the digital divide with additional clickthroughs.

Production

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting,

01

Production Process

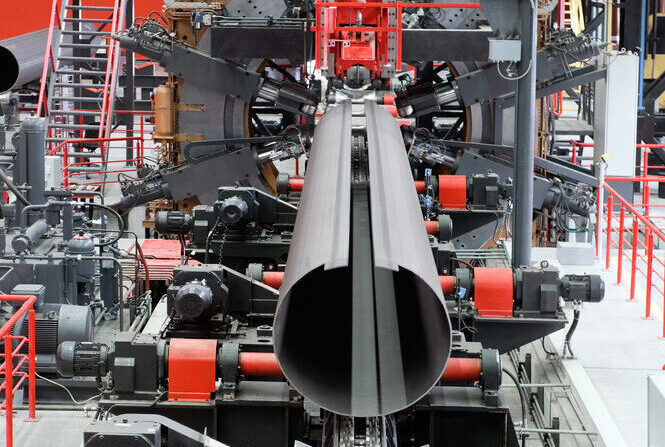

The Kami Pipe is a highly effecient production unit capable of meeting the customer’s varying requirements with in our production range. During production great attention is placed by Kami Pipe on the quality level of the weld area. Kami Pipe uses Japanese Technology based High Frequency plant and the technology based pipe mill in order to maintain a strong and sound weld strength accurate pipe size.

02

Quality Standards

Kami Industries manufactures H.R. and C.R. welded pipes and tubes through high frequency induction technology in confirmance with different standards in accordance to the utilization purposes and additional customer’s specifications. Every member of the staff of Kami Pipe has the common goal to exceed the customer’s expectations. When it comes to construction and design,

03

weight & coating

Individual pipe lengths are rolled onto a weighing table the resulting weight measurement and prior inspection data are transmitted to a digital read- out screen and printed onto a paper reorder for customer and factory record random inspection checks are also performed as well as verification of the pipe. (The length and final marking as per the requirements of the client performed at this stage). To meet the added requirements of the line pipe industry and in keeping with its commitment to provide the highest quality product Kami Pipe has further enhanced its coating facilities.

04

Quality Policy

We are committed to establish, maintain and improve our quality management system which will ensure specified product quality . for our tubing and pipes. We will ensure that customer requirements are met as per schedule consistently from the first day of supply. Our eritesion of success is zero complaints and total customer satisfaction.

05

Quality Objectives

Improving the productivity through optimizing the effectiveness of maintenance by importing proper training to employees so that the desired result can be achieved. Ensure smooth and trouble free operation of plant and equipment by providing high quality maintenance services in cost effective manner to raise efficiency of machine.

06

Quality Test & Certificate

Mechanical test, visual and dimensional inspection, other test compliance, with standard specification “1 to 6”.

Product test certificate from our mil are also issued upon request